Application Of Slewing Bearing In Machine Tool Industry

Jingwei Slewing Bearing is a leading company in China's slewing bearing market. We are committed to providing various standard and non-standard slewing bearing solutions for the machinery industry. If you have more questions forslewing rings and table bearings assembling, our in house engineers will pay attention to this parts and provide solutions to you.

Jingwei slewing bearings are widely applicationto the machinery industry and provide excellent precision for smoothly running. We do a lot of job in reducing weight, creating space, reducing friction and extending durable life. Fenghe offers a variety of raw materials, internal assembling, grease and corrosion resistance options. Fenghe offers the widest range of slewing bearings with P.C.D of 120mm to 5500mm.

Jingwei slewing ring is suitable for all kinds of harsh environments. Our technical research and development personnel focus on sealing protection during the slewing bearing operation, which effectively guarantees the internal lubrication of the slewing ring and prolongs the durable life.

As the main engine supporting manufacturer of China's machinery industry, we have provided stable and reliable slewing bearing operation solutions for XCMG, SANY CSGC and Zoomlion for a long time. Given Jingwei's expertise in slewing bearings, we keep closely with mechanical equipment designers to provide machinery industries cost-effective and value-added solution.

Slewing ring

Light series slewing ring

Single-row four point contact ball slewing ring

Single-row cross roller slewing ring

Double rows ball slewing ring

Three rows of roller slewing bearing

Application

Excavator

Stacker and reclaimer

Dynamic compactor

Crawler crane

Long spiral drilling equipment

Wheeled crane

Tower crane

Cargo crane

Concrete pump truck

Roadheader

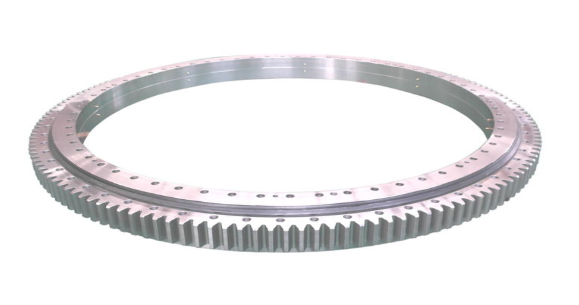

Slewing bearing In the machine tool industry, the slewing bearing of standard structure adopts high-precision grade while applying preload to eliminate clearance and reduce vibration.

The radial run out and diameter tolerance of the slewing bearing range from one thousandth to one ten thousandth of an inch (2.54 tan), the structure is compact, the cross-sectional size is small, and the diameter range can be as small as 50 mm (this type of slewing bearing steel ball The size is smaller than the steel ball size of the heavy series slewing bearing traditionally used). This prompted designers to begin to reconsider the traditional slewing bearing configuration.

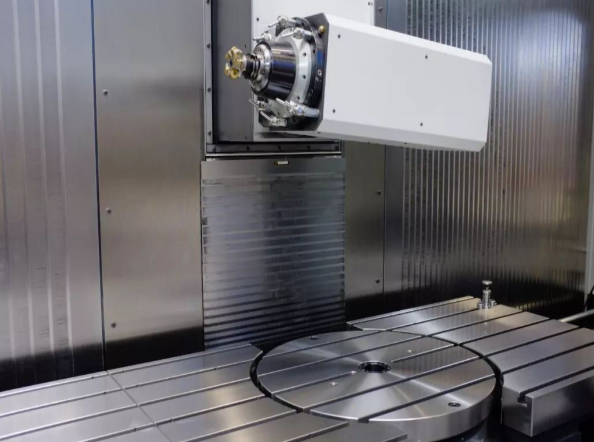

The hanger column bearing used to bear radial, axial and moment loads is installed with two sets of ball or roller slewing bearings spaced along the shaft. This configuration is achieved by placing two sets of slewing bearings on the shaft for a long distance Set to obtain higher moment load capacity. However, for this configuration, due to space constraints and installation complexity, it is difficult to adapt to new applications, and this is the advantage of slewing bearings.

Using one set of slewing bearings instead of two sets of slewing bearings can not only reduce the height of the device, but also simplify the assembly structure. Therefore, the slewing bearings are particularly suitable for new operating devices in industrial automation.

The correct choice of slewing bearing depends on the requirements of load, stiffness, speed, size and rotational flexibility. The user and the slewing bearing manufacturer jointly discuss the design goals and the suitability of the slewing bearing, which helps to optimize the performance of the system under the premise of the lowest cost and the guarantee of trouble-free operation.

It is just right to choose Jiangsu Shuangzheng with slewing bearing.

© Copyright: 2026 MA ANSHAN JING WEI SLEWING RING CO.,LTD. All Rights Reserved.

IPv6 network supported