Slewing drive is a kind of all-round slewing decelerating transmission mechanism integrated with driving power source. It uses slewing ring as driving follower and mechanism attachment. By attaching the driving part, driving source and cover on one of the inner and outer rings of slewing ring, the other ring is regarded as both the driving follower and the connecting base of the driven working parts. In this way, slewing ring is used It is the feature of all-round rotation connecting piece. It is a general-purpose decelerating transmission mechanism which integrates the functions of rotation, deceleration and driving, but also has simple structure and convenient manufacture and maintenance.

-

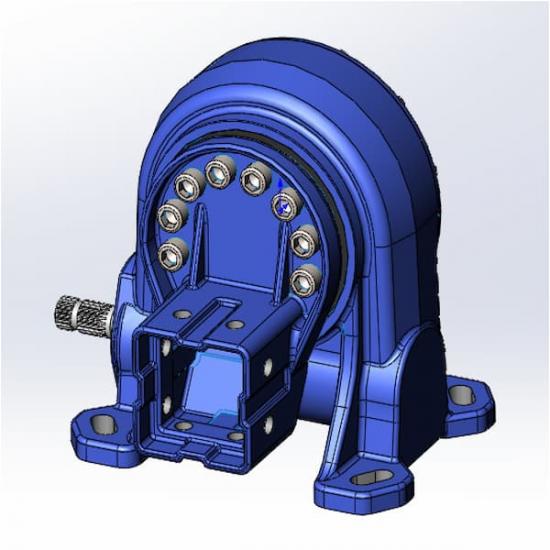

Double Row Linkage Reducer

Name: Double row linkage reducer

Introduction:

In the field of new energy photovoltaic power generation, reducers are often used in the transmission system as the core transmission components. By connecting pipes to the output end of the reducer and installing solar panels on the square tubes, the reducer drives the square tubes and solar panels to rotate and shift, thereby improving the power generation efficiency of the solar panels.

This is the JV6B series of our company's double-row linkage reducer. The system can drive the solar panels on two mounting brackets to rotate and shift through one motor, which improves the transmission efficiency of the system for rotating the solar panels and reduces the power consumption of the system during use. Moreover, the two reducers are connected by a single transmission shaft, and only one motor is needed to drive the other reducer to rotate synchronously. The output transmission is more stable, prolonging the power generation life of the system.

-

All-terrain Photovoltaic Tracking Drive

Name: All-terrain Photovoltaic Tracking Drive

Introduction:

In the field of new energy photovoltaic power generation, with the continuous tightening of the national photovoltaic land policy, there is less flat land suitable for the construction of tracking power stations.

-

Eccentric Tracking Drive

Name: Eccentric Tracking Drive

Introduction:

This is an improved version of the JV series in the company's photovoltaic tracking drive, providing an eccentric vertical reducer that is easy to maintain, which can reduce the load function of the reducer.

Features of this product:

1.Easy maintenance and installation

2. More torque

3. Reduce the speed reducer load

-

Mechanical Multi-Drive

Name: Mechanical Multi-Drive

Introduction:

In the field of new energy photovoltaic power generation, the reducer is often used in the transmission system as the core transmission component. By connecting the pipe to the output end of the drive, the solar panel is installed on the square pipe, and the reducer drives the square pipe and the solar panel to flip and transfer to improve the power generation efficiency of the solar panel.

This is our company photovoltaic reducer in JL series, flat uniaxial multi-transmission system with reducer, system can through a motor drive multiple solar panels on the bracket, improve the efficiency of the system of solar panels, and reduce the power consumption of the system in use, and between multiple reducer through multiple transmission shaft connection, only need a motor can drive multiple platform reducer synchronous rotation, output transmission more stable, extend the life of the system.

-

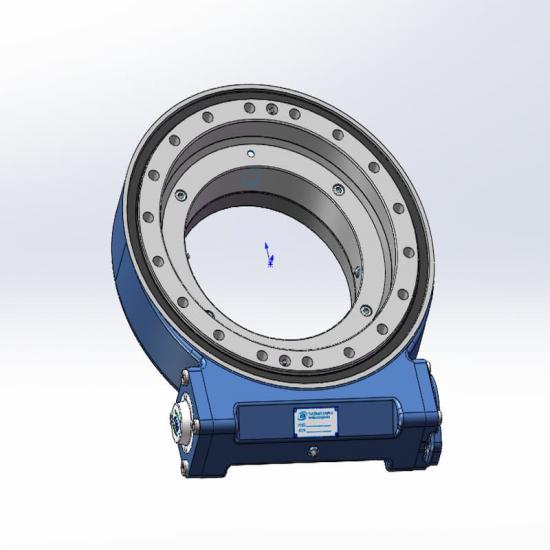

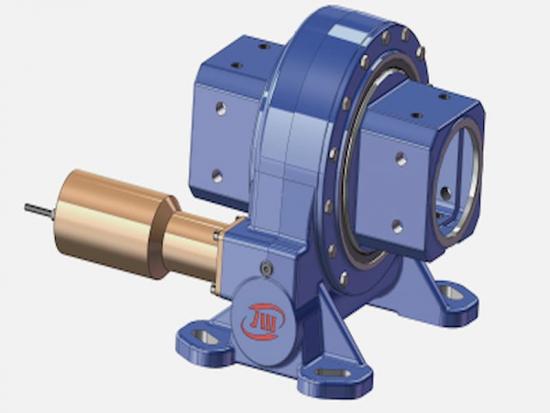

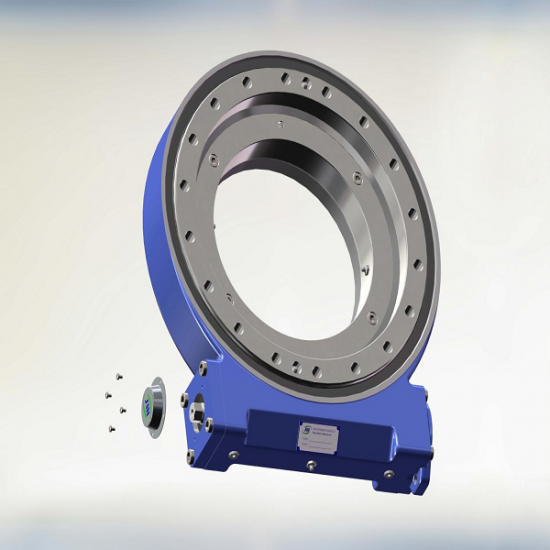

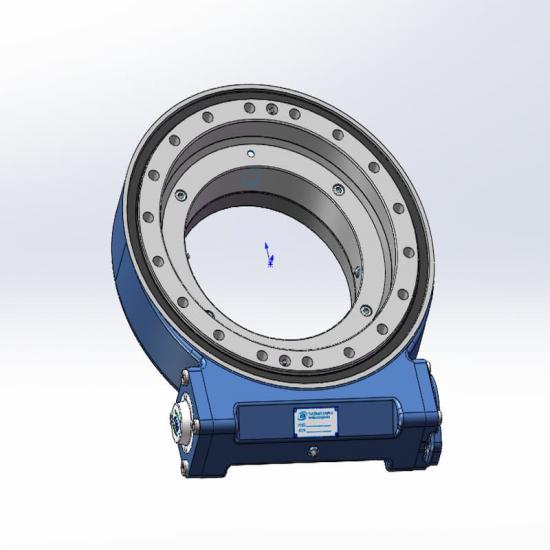

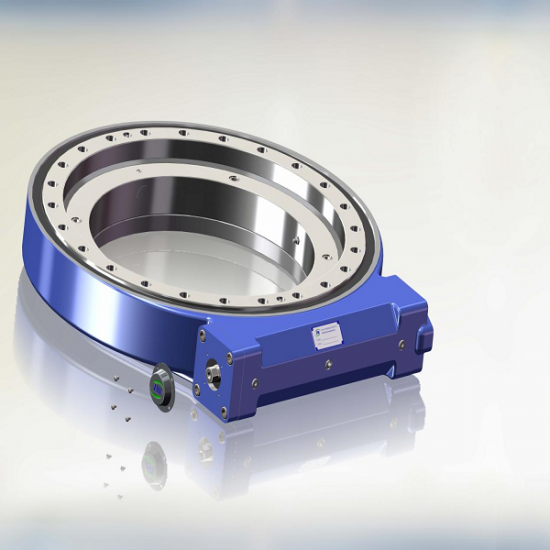

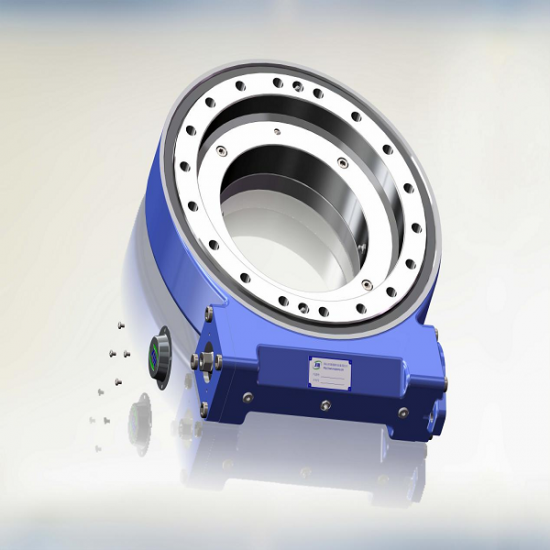

High precision JP series rotary reducer

Name: High precision JP series rotary reducer

Introduction:

This company's high-precision JP series rotary reducer is an important engineering equipment, its internal structure uses steel wire raceway, the working principle makes it suitable for a variety of industrial and engineering applications. These devices improve the function of various equipment and machinery by driving motors, reducers, gears, bearings, hydraulic systems and control systems to achieve horizontal and vertical rotational motion.

-

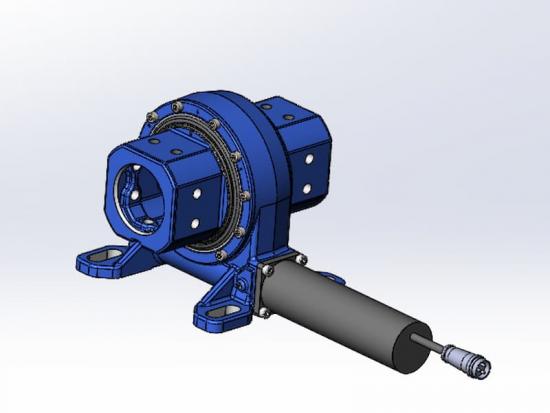

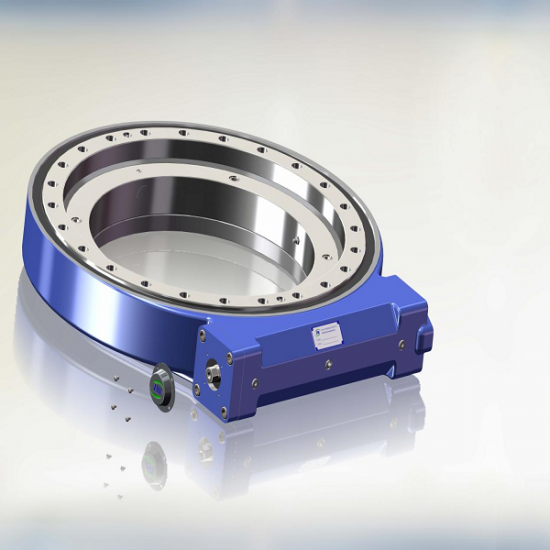

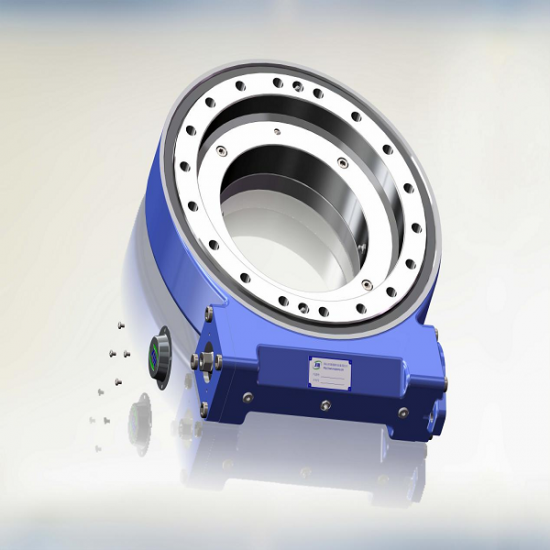

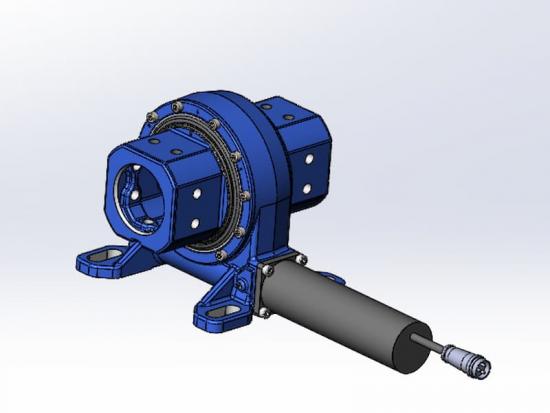

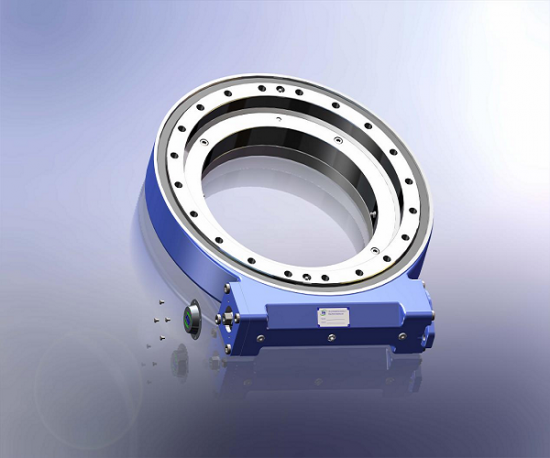

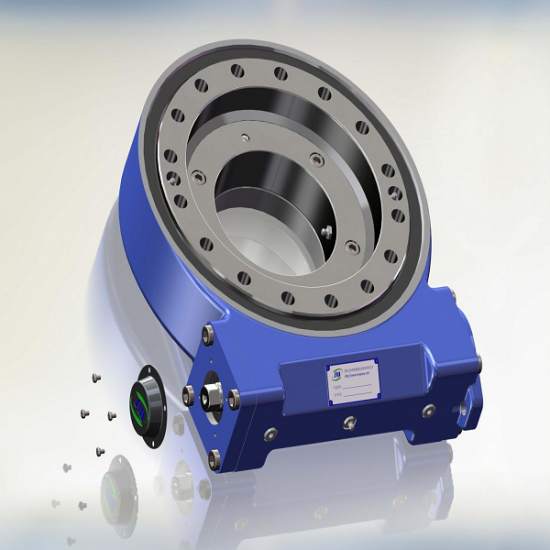

Closed rotary reducer

Name: Closed rotary reducer

Introduction:

This enclosed rotary reducer is compact and suitable for applications with limited space and speeds below 1 RPM. The spiral shape of the worm and worm gear provides high transmission accuracy, making it suitable for applications requiring stable rotation and position control.

-

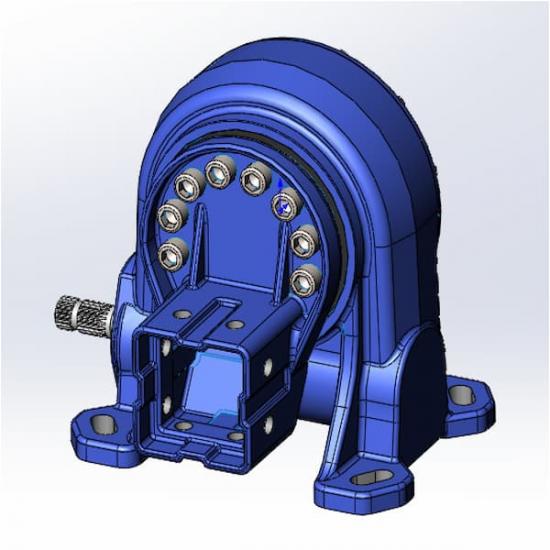

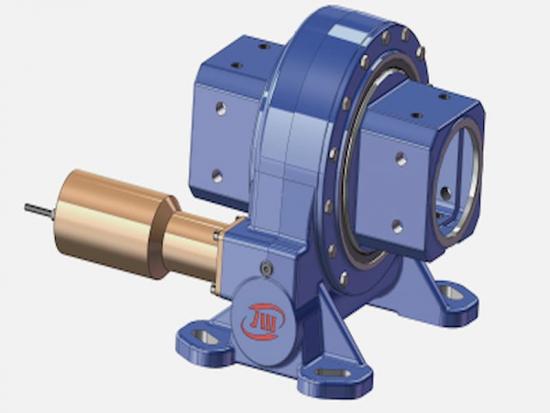

Traditional single point electrical linkage reducer

Name: Traditional single point electrical linkage reducer

Introduction:

This is the company's traditional single-point electrical linkage reducer, mainly used in solar tracking and various industrial and manufacturing fields, bringing precise reliability. The torus enveloping worm structure allows for maximum gear contact for higher strength and output torque.

-

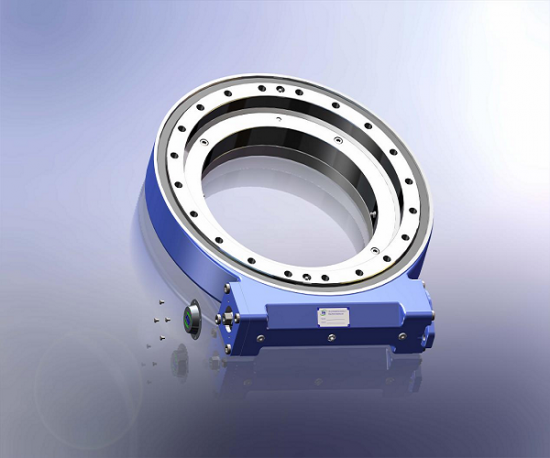

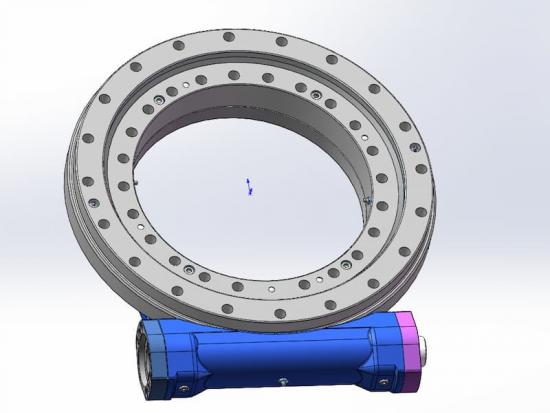

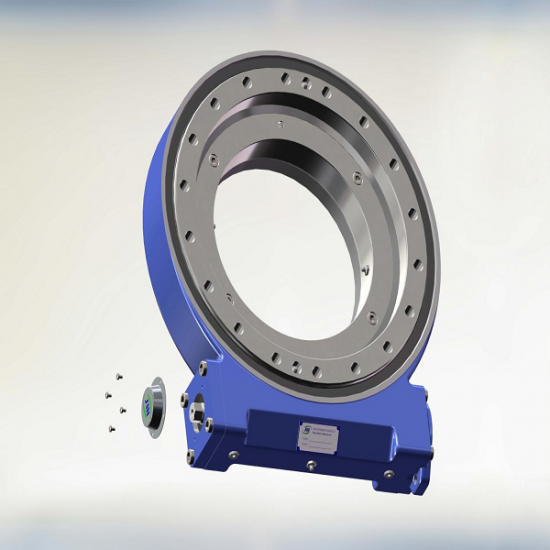

Open rotary speed reducer

Name:Open rotary speed reducer

Introduction:

This is an important engineering device of our company, whose open housing structure and working principle make it suitable for a variety of manufacturing equipment with simple operation and low cost maintenance.

-

Dedicated Tracking Drive For The Closed Spindle

Introduction:

This is the JM series in the company's photovoltaic reducer, which is suitable for double-row vertical discharge structure, and the main shaft does not need to open to avoid the motor. At the same time, it is also the first push of electrical linkage.

-

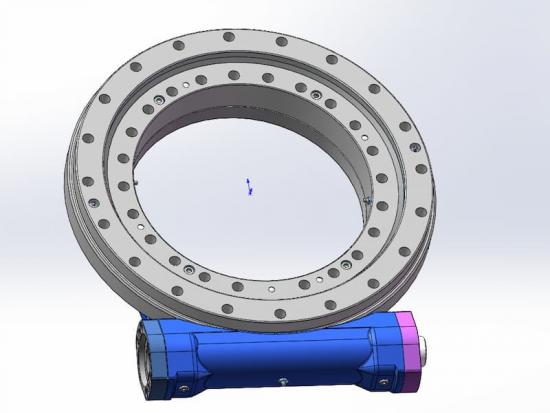

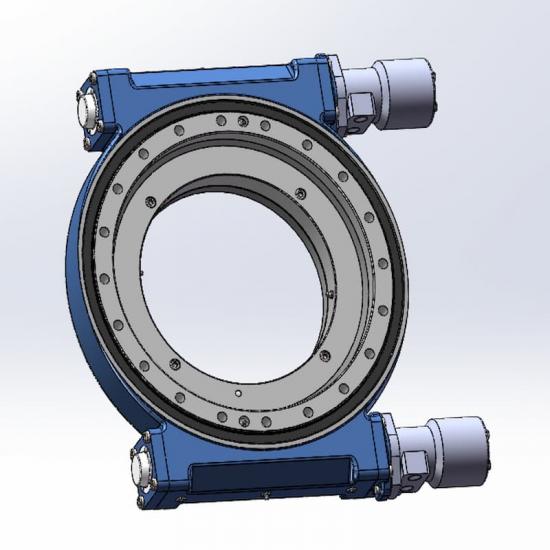

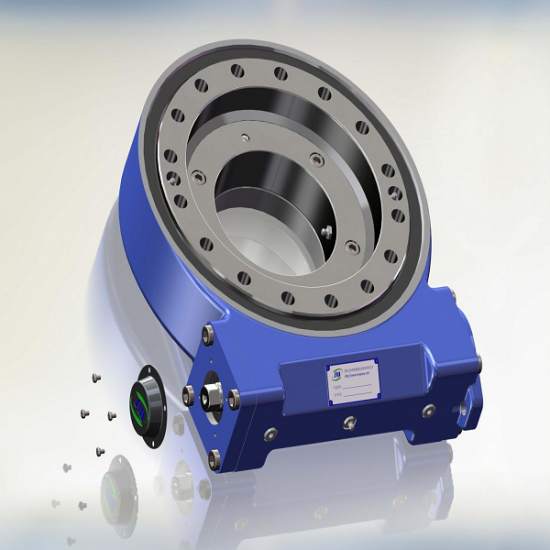

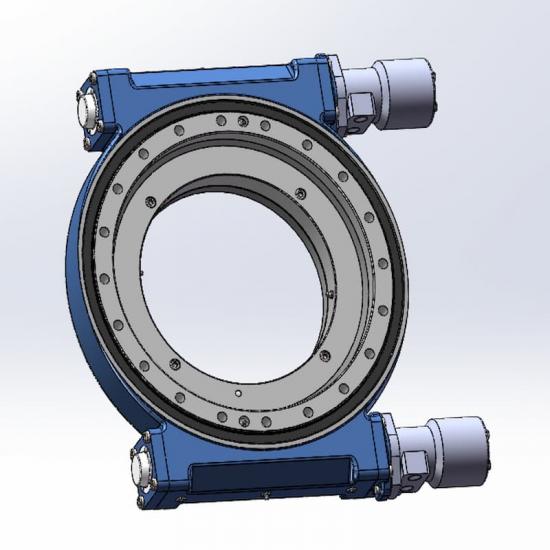

Double worm rotary reducer

Name: Double worm rotary reducer

Introduction:

This is the company's double worm type slewing reducer device is assembled by vertical fence type base, slewing support, 2 worm and supporting parts, can have 2 motors or hydraulic motors at the same time to drive the device rotation, in the ordinary fence foundation can reach 2 times tooth contact. Under the same volume and installation space, it can produce nearly double the output torque, which greatly improves the performance of the product, and the holding torque is also doubled.

-

JS21 slewing reducer series

Product features:

1. The horizontal structure allows the product to be installed horizontally, vertically, and obliquely, with the characteristics of flexible and diverse installation. Compared with other types of reducers, it has the characteristics of small volume, easy installation and maintenance.

2. The product adopts a blind hole design and a skeleton oil seal structure, with reliable sealing performance. The sealing area can avoid direct sunlight, effectively dust-proof and waterproof, and the protection level can reach IP65, suitable for outdoor use.

3. Use specialized machine tools and equipment to produce toroidal worm gears with multiple teeth in contact, transmitting greater torque and being able to withstand greater axial, radial, and overturning forces.

4. The product design adopts universal dimensions both domestically and internationally, making it convenient for later replacement.

Application scope:

1. Used for the horizontal rotation of solar tracking systems, and can also be applied to the rotation of certain special engineering machinery and industrial equipment. Various types of construction machinery chassis rotation or boom rotationRotation of the chassis of high-altitude work vehicles

2. Applied to photovoltaic single and dual axis tracking systems, concentrated photovoltaic tracking systems, tower style heliostats, dish style Stirling power generation, trough style concentrated heat generation heating systems, etc.

Application advantages:

1. The surface of the product is subject to secondary electrostatic powder spraying in multiple processes, and the use of epoxy zinc rich primer and epoxy resin flour greatly improves the corrosion resistance and aging resistance of the product. Neutral salt spray test for more than 1000 hours.

2. The raceway and gear tooth surface of the slewing support have undergone quenching treatment, resulting in high hardness and strong rigidity.

3. It has a self-locking function, which improves the safety of use.

4. The transmission accuracy can reach 1 milliradian (1mard).

5. The product is developed based on the principle of maintenance free, with minimal maintenance.

6. The load and overturning torque borne by the product are greater than those of similar products in the market.

7. The product has undergone high and low temperature tests and has strong temperature resistance.

8. Adopting national high-tech graphene synthetic lubricating grease, its lifespan and heat dissipation efficiency far exceed ordinary lubricating grease.

9. Adopting a toroidal worm design, with multiple teeth in contact and carrying a large output torque.

-

JS17 slewing reducer series

Product features:

1. The horizontal structure allows the product to be installed horizontally, vertically, and obliquely, with the characteristics of flexible and diverse installation. Compared with other types of reducers, it has the characteristics of small volume, easy installation and maintenance.

2. The product adopts a blind hole design and a skeleton oil seal structure, with reliable sealing performance. The sealing area can avoid direct sunlight, effectively dust-proof and waterproof, and the protection level can reach IP65, suitable for outdoor use.

3. Use specialized machine tools and equipment to produce toroidal worm gears with multiple teeth in contact, transmitting greater torque and being able to withstand greater axial, radial, and overturning forces.

4. The product design adopts universal dimensions both domestically and internationally, making it convenient for later replacement.

Application scope:

1. Used for the horizontal rotation of solar tracking systems, and can also be applied to the rotation of certain special engineering machinery and industrial equipment.

Various types of construction machinery chassis rotation or boom rotation

Rotation of the chassis of high-altitude work vehicles

2. Applied to photovoltaic single and dual axis tracking systems, concentrated photovoltaic tracking systems, tower style heliostats, dish style Stirling power generation, trough style concentrated heat generation heating systems, etc.

Application advantages:

1. The surface of the product is subject to secondary electrostatic powder spraying in multiple processes, and the use of epoxy zinc rich primer and epoxy resin flour greatly improves the corrosion resistance and aging resistance of the product. Neutral salt spray test for more than 1000 hours.

2. The raceway and gear tooth surface of the slewing support have undergone quenching treatment, resulting in high hardness and strong rigidity.

3. It has a self-locking function, which improves the safety of use.

4. The transmission accuracy can reach 1 milliradian (1mard).

5. The product is developed based on the principle of maintenance free, with minimal maintenance.

6. The load and overturning torque borne by the product are greater than those of similar products in the market.

7. The product has undergone high and low temperature tests and has strong temperature resistance.

8. Adopting national high-tech graphene synthetic lubricating grease, its lifespan and heat dissipation efficiency far exceed ordinary lubricating grease.

9. Adopting a toroidal worm design, with multiple teeth in contact and carrying a large output torque.

-

JS14 slewing reducer series

Product features:

1. The horizontal structure allows the product to be installed horizontally, vertically, and obliquely, with the characteristics of flexible and diverse installation. Compared with other types of reducers, it has the characteristics of small volume, easy installation and maintenance.

2. The product adopts a blind hole design and a skeleton oil seal structure, with reliable sealing performance. The sealing area can avoid direct sunlight, effectively dust-proof and waterproof, and the protection level can reach IP65, suitable for outdoor use.

3. Use specialized machine tools and equipment to produce toroidal worm gears with multiple teeth in contact, transmitting greater torque and being able to withstand greater axial, radial, and overturning forces.

4. The product design adopts universal dimensions both domestically and internationally, making it convenient for later replacement.

Application scope:

1. Used for the horizontal rotation of solar tracking systems, and can also be applied to the rotation of certain special engineering machinery and industrial equipment.

Various types of construction machinery chassis rotation or boom rotation

Rotation of the chassis of high-altitude work vehicles

2. Applied to photovoltaic single and dual axis tracking systems, concentrated photovoltaic tracking systems, tower style heliostats, dish style Stirling power generation, trough style concentrated heat generation heating systems, etc.

Application advantages:

1. The surface of the product is subject to secondary electrostatic powder spraying in multiple processes, and the use of epoxy zinc rich primer and epoxy resin flour greatly improves the corrosion resistance and aging resistance of the product. Neutral salt spray test for more than 1000 hours.

2. The raceway and gear tooth surface of the slewing support have undergone quenching treatment, resulting in high hardness and strong rigidity.

3. It has a self-locking function, which improves the safety of use.

4. The transmission accuracy can reach 1 milliradian (1mard).

5. The product is developed based on the principle of maintenance free, with minimal maintenance.

6. The load and overturning torque borne by the product are greater than those of similar products in the market.

7. The product has undergone high and low temperature tests and has strong temperature resistance.

8. Adopting national high-tech graphene synthetic lubricating grease, its lifespan and heat dissipation efficiency far exceed ordinary lubricating grease.

9. Adopting a toroidal worm design, with multiple teeth in contact and carrying a large output torque.

-

JS12 slewing reducer series

Product features:

1. The horizontal structure allows the product to be installed horizontally, vertically, and obliquely, with the characteristics of flexible and diverse installation. Compared with other types of reducers, it has the characteristics of small volume, easy installation and maintenance.

2. The product adopts a blind hole design and a skeleton oil seal structure, with reliable sealing performance. The sealing area can avoid direct sunlight, effectively dust-proof and waterproof, and the protection level can reach IP65, suitable for outdoor use.

3. Use specialized machine tools and equipment to produce toroidal worm gears with multiple teeth in contact, transmitting greater torque and being able to withstand greater axial, radial, and overturning forces.

4. The product design adopts universal dimensions both domestically and internationally, making it convenient for later replacement.

Application scope:

1. Used for the horizontal rotation of solar tracking systems, and can also be applied to the rotation of certain special engineering machinery and industrial equipment.

Various types of construction machinery chassis rotation or boom rotation

Rotation of the chassis of high-altitude work vehicles

2. Applied to photovoltaic single and dual axis tracking systems, concentrated photovoltaic tracking systems, tower style heliostats, dish style Stirling power generation, trough style concentrated heat generation heating systems, etc.

Application advantages:

1. The surface of the product is subject to secondary electrostatic powder spraying in multiple processes, and the use of epoxy zinc rich primer and epoxy resin flour greatly improves the corrosion resistance and aging resistance of the product. Neutral salt spray test for more than 1000 hours.

2. The raceway and gear tooth surface of the slewing support have undergone quenching treatment, resulting in high hardness and strong rigidity.

3. It has a self-locking function, which improves the safety of use.

4. The transmission accuracy can reach 1 milliradian (1mard).

5. The product is developed based on the principle of maintenance free, with minimal maintenance.

6. The load and overturning torque borne by the product are greater than those of similar products in the market.

7. The product has undergone high and low temperature tests and has strong temperature resistance.

8. Adopting national high-tech graphene synthetic lubricating grease, its lifespan and heat dissipation efficiency far exceed ordinary lubricating grease.

9. Adopting a toroidal worm design, with multiple teeth in contact and carrying a large output torque.

-

JS9 slewing reducer series

Product features:

1. The horizontal structure allows the product to be installed horizontally, vertically, and obliquely, with the characteristics of flexible and diverse installation. Compared with other types of reducers, it has the characteristics of small volume, easy installation and maintenance.

2. The product adopts a blind hole design and a skeleton oil seal structure, with reliable sealing performance. The sealing area can avoid direct sunlight, effectively dust-proof and waterproof, and the protection level can reach IP65, suitable for outdoor use.

3. Use specialized machine tools and equipment to produce toroidal worm gears with multiple teeth in contact, transmitting greater torque and being able to withstand greater axial, radial, and overturning forces.

4. The product design adopts universal dimensions both domestically and internationally, making it convenient for later replacement.

Application scope:

1. Used for the horizontal rotation of solar tracking systems, and can also be applied to the rotation of certain special engineering machinery and industrial equipment.

Various types of construction machinery chassis rotation or boom rotation

Rotation of the chassis of high-altitude work vehicles

2. Applied to photovoltaic single and dual axis tracking systems, concentrated photovoltaic tracking systems, tower style heliostats, dish style Stirling power generation, trough style concentrated heat generation heating systems, etc.

Application advantages:

1. The surface of the product is subject to secondary electrostatic powder spraying in multiple processes, and the use of epoxy zinc rich primer and epoxy resin flour greatly improves the corrosion resistance and aging resistance of the product. Neutral salt spray test for more than 1000 hours.

2. The raceway and gear tooth surface of the slewing support have undergone quenching treatment, resulting in high hardness and strong rigidity.

3. It has a self-locking function, which improves the safety of use.

4. The transmission accuracy can reach 1 milliradian (1mard).

5. The product is developed based on the principle of maintenance free, with minimal maintenance.

6. The load and overturning torque borne by the product are greater than those of similar products in the market.

7. The product has undergone high and low temperature tests and has strong temperature resistance.

8. Adopting national high-tech graphene synthetic lubricating grease, its lifespan and heat dissipation efficiency far exceed ordinary lubricating grease.

9. Adopting a toroidal worm design, with multiple teeth in contact and carrying a large output torque.