Single row four point contact Slewing Bearing can be customized to meet the user’s different working conditions and normal working conditions in the environment, providing excellent axial, radial and titling moments. Mainly used in radar, military turrets, machine tools and excavators.

Product Origin:

ChinaItem NO.:

HS seriesShipping Port:

ShanghaiColor:

Customer wantsLead Time:

From 40 days to 60 daysPayment:

FOB

The brand of single row four point contact slewing bearing is MAANSHAN JINGWEI SLEWING RING CO.,LTD. The product is packed in wooden cases, which can be exported. The application scope of this product is construction machinery.

Note:

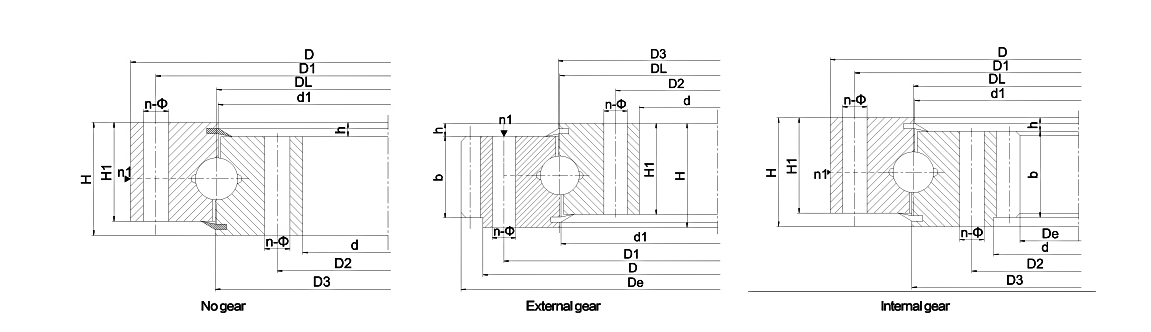

1.n1 is No. of lube holes, the user can specify the lube hole position.

2.n-φ can be changed to threading holes, hole diameter M, thread depth 2M.

3.There are standard products in the catalog, and the inner and outer diameters are random tolerances. If there is a locating requirement for slewing bearing, please indicate the site and tolerance.

4.It is standard type of our products, if you need more please contact with engineer.

In heavy duty applications with frequent rotation, premature failure is a common failure of large diameter slewing bearings. In large rotating equipment such as cranes, excavators and tunnel boring machines, the slewing bearing must simultaneously deal with various combinations of complex axial, radial and tilt moment loads. If it is maintained regularly, 96% of the slewing bearing failures can be prevented. In order to prolong the bearing life to the maximum extent, it is only necessary to lubricate the raceway and gear, check the bolt torque and seal.

Slewing ring lubrication

Use extreme pressure lithium grease to lubricate and maintain the Fenghe slewing bearing according to the user's operation manual. The slowly rotating equipment shall be fully lubricated every 100 hours. More frequent lubrication may be required on fast moving or continuously rotating equipment, even every 8 hours a day. At the same time of adding lubricating grease, fill it up until the seal overflows, which can effectively extrude the impurities inside the slewing ring and effectively clean the inside. If it is not used for a long time, the grease of the slewing ring will dry, thus forming condensation in the slewing ring. We can avoid this by injecting new grease at least every six months.

Gear lubrication

Generally, the inner ring or outer ring of the slewing bearing has teeth. At this time, it is necessary to use the pinion to drive. As the Meshing Effect of the teeth is easy to extrude the grease, the gear should be lubricated every 6 hours on the slow rotation or intermittent rotation equipment, that is, a small amount of grease should be introduced at the meshing point between the gear and the slewing bearing ring gear.

Sealing element

The seals on the bearings shall be visually inspected on a regular basis to ensure that they are in good condition. Many people have neglected the importance of seals, but they help to a great extent to prevent contamination of the slewing ring raceway.

Bolt

Vibration and impact tend to loosen bolts, but periodic torque checks and tightening will help to maintain proper preload levels. Torque check of bolts should be part of routine maintenance procedures. The mounting bolts shall be torqued to the proper level and checked periodically to ensure proper preload. Bolt creep is another factor that should be monitored. The tightened bolt will creep or stretch over a period of time, thus reducing the preload.

Prev :

Good Quality Cheap China Customized Three Row Column Slewing RingNext :

Single cross roller(series HJ)Email us with any questions or inquiries or use our contact data. We would be happy to answer your questions.

Categories

© Copyright: 2026 MA ANSHAN JING WEI SLEWING RING CO.,LTD. All Rights Reserved.

IPv6 network supported