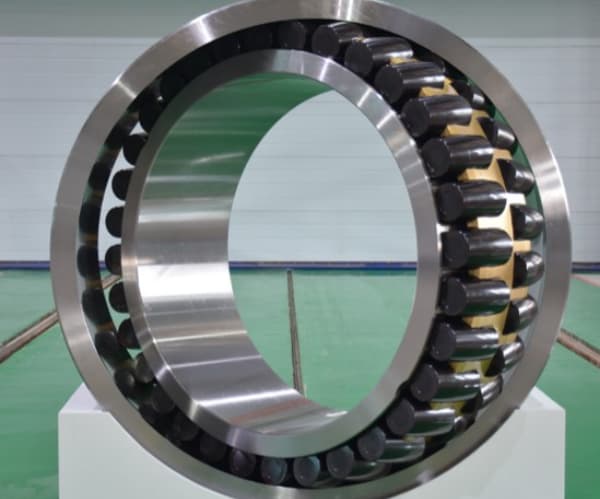

Recently, the project "R&D and Application of Wind Turbine SRB Main Shaft Bearings," led by MAANSHAN JING WEI SLEWING BEARING CO.,LTD was appraised by experts organized by the Anhui Province Machinery Industry Federation. It was recognized as having overall technology reaching international advanced and domestic leading levels. This achievement marks a significant breakthrough for China in the key field of wind turbine main shaft bearings, providing strong support for promoting the localization of wind power equipment. The project focuses on long-standing "bottleneck" problems in the manufacturing of wind turbine main shaft bearings—specifically, the lack of soft-band quenching technology. Through multiple improvements and experimental verifications, Jingwei, in collaboration with partners, successfully developed equipment and a supporting process system for soft-band-free quenching with independent intellectual property rights. This effectively breaks through foreign technological monopolies and addresses industry pain points such as high costs and low efficiency in traditional quenching processes. In terms of innovative achievements, the project realizes three major breakthroughs: · Material System Innovation: By adding trace alloy elements, a new type of ring material with high strength and high hardenability is developed, better matching the requirements of soft-band-free induction quenching processes. · Process Control Breakthrough: High-precision accompanying tracking technology for quenching inductors is developed, overcoming the challenge of controlling the uniformity of hardened layers in large bearings. · Design Method Upgrade: A new bearing design software is independently developed, effectively solving system coupling deformation problems under complex working conditions. Currently, the product has passed certification by the Beijing Jianheng Certification Center, and all performance indicators meet the 20-year service life requirements for onshore wind turbine main bearings. It has been applied in Mingyang Smart Energy Group. The project has cumulatively applied for 4 invention patents, obtained 1 authorized utility model patent and 3 software copyrights, and participated in the formulation of 1 national standard, demonstrating good technical maturity and industrial application prospects. It is understood that in recent years, Jingwei has continuously increased R&D investment in areas such as wind turbine SRB, TRB, DTRB main shaft bearings, and intelligent tracking photovoltaics, achieving multiple progress results. The company's photovoltaic tracking reducers have been exported to many countries in Europe, North America, South America, the Middle East, and the Belt and Road region, generating hundreds of millions of yuan in foreign exchange revenue annually. This technological breakthrough not only reflects Jingwei's innovative strength in the field of high-end bearings but also provides a reliable and c...

The National and Group Standards for Wind Turbine Seals and Smart PV Tracking Systems, in which Jingwei participated in drafting, have been officially released. Recently, the National Standardization Administration and relevant industry organizations officially released the National Standard GB/T 33154-2025 "Rubber Seals for Yaw Bearings and Pitch Bearings of Wind Turbines" and the Group Standard T/CI 1083-2025 "Smart Tracking PV Mounting Systems." MAANSHAN JINGWEI NEW ENERGY DRIVE EQUIPMENT Co., LTD . and its subsidiary MAANSHAN JINGWEI NEW ENERGY DRIVE EQUIPMENT Co., LTD served as key drafting units, deeply involved in the technical review and drafting of both standards, marking another recognition of the company's technical strength in wind turbine sealing and PV tracking systems. The two standards focus on key components and technological systems in the new energy industry, aiming to further improve the technical specification system for wind and PV sectors and provide crucial technical support for achieving the "dual carbon" goals. GB/T 33154-2025 systematically regulates the performance requirements of rubber seals for yaw and pitch bearings throughout their lifecycle. The new standard introduces specifications for multi-lip seal structural design, establishes a precise dimensional tolerance system, and sets stricter finished product performance indicators, meeting the sealing reliability demands of wind farms in extreme environments such as high/low temperatures, strong UV exposure, and high salt spray. T/CI 1083-2025 focuses on the intelligent upgrade of PV tracking systems, clarifying key performance parameters such as tracking accuracy, wind resistance, and seismic resistance, promoting the expansion of mounting systems from flat terrains to complex scenarios like mountainous and water surfaces, and providing an important technical basis for improving the overall power generation efficiency and system reliability of PV power plants. As an enterprise in the wind and PV new energy sector, Jingwei has long been deeply engaged in R&D for critical technologies in sealing systems and new energy equipment, continuously increasing R&D investment, and building a full-chain technical system covering material formulation, structural design, and performance testing. During the drafting of GB/T 33154-2025, Jingwei actively contributed its engineering experience in sealing structure and material performance, collaboratively promoting the implementation of related technologies. In T/CI 1083-2025, it assisted in demonstrating technical parameters for the adaptation between tracking systems and seals, effectively driving the transformation of corporate innovation achievements into industry-wide norms. In the future, Jingwei will leverage the release of these two standards to continue deepening R&D investment, promoting the coordinated improvement of technological innovation and standardization in the new energy ...

Recently, Yichang Changji Technology Co., Ltd. (hereinafter referred to as "Changji Technology") awarded Maanshan Jingwei Slewing Bearing Co., Ltd's Equipment Department Director Chen Bin with the "Excellent Suggestion Award" for product improvement, in recognition of his multiple practical suggestions during the product experience process. These suggestions were closely integrated with actual application scenarios, providing valuable insights for Changji Technology to optimize product details and enhance user experience. As a close partner of Jingwei, Changji Technology has continuously deepened cooperation with Jingwei in equipment supply and technical collaboration over the years. This award not only reflects the efficient collaboration between the two parties but also further solidifies their cooperative foundation of "mutual trust, mutual advancement, and empowering win-win." Jingwei always regards talent as an important driving force for enterprise development. While continuously improving its internal talent training system, it also highly values the professional wisdom from partners. Chen Bin effectively identified optimization opportunities in product usage details based on his profound accumulation in equipment management and frontline insights, with suggestions closely aligned with practical application scenarios. Jingwei also actively responds to feedback from customers and suppliers with an open attitude, jointly refining product strength and promoting industrial chain collaborative innovation.

On November 16, 2025, Maanshan Jingwei Slewing Bearing Co., LTD. was awarded the "Excellence in Service Award" by its long-term partner, Mingyang Smart Energy Group, in recognition of its outstanding service performance. This honor reflects the company's professional capabilities and sustained commitment to customer service. As a long-term strategic partner of Mingyang Smart Energy, JINGWEI has always adhered to the "customer-first" service philosophy, establishing a comprehensive service system. By accurately understanding customer needs, optimizing service processes, strengthening technical support, and improving response efficiency, the company continues to provide full-range, high-standard service guarantees. The partnership is built on a solid foundation of mutual trust. Over the years, JINGWEI has earned Mingyang Smart Energy's high trust through the excellent performance and stable quality of its wind turbine bearings, complemented by professional and efficient service support. This trust is reflected not only in ongoing business collaboration but also in technical exchanges, product innovation, and after-sales service. Through long-term cooperation, the two companies have developed an efficient and collaborative working mechanism. JINGWEI continuously enhances the service experience through regular follow-ups, demand research, and rapid response systems, while Mingyang Smart Energy provides timely feedback and constructive suggestions to help improve service quality. This positive interaction has fostered mutual growth and built a solid strategic partnership. Winning the "Excellence in Service Award" is not only a recognition of Jingwei's capabilities but also a significant milestone in the deepening of the partnership. Looking ahead, JINGWEI will continue to uphold its "customer-centric" service philosophy, further strengthen strategic cooperation with Mingyang Smart Energy, and create greater value for its partners through technological innovation and quality upgrades, achieving mutual benefits and win-win outcomes.

In the second half of 2025, the 16th Construction Machinery Industry Brand Summit concluded successfully at the Guoce International Conference & Exhibition Center in Beijing. Maanshan Jingwei Slewing Bearing Co., Ltd. was awarded the "2025 High-Quality Transmission System Component Supplier" title, showcasing its technical expertise and superior product quality in the high-end transmission components sector. Hosted by HC360 Construction Machinery Network, the summit, themed "Building Brands, Strengthening Technology, Shaping Corporate Power and Value," gathered industry experts and leading enterprises. The awards were selected through a rigorous multi-dimensional evaluation process, including online voting, customer satisfaction surveys, and expert reviews. Jingwei's recognition stems from its continuous technological innovation, refined quality control systems, and consistently reliable product performance, earning unanimous praise from clients and industry professionals. As a national high-tech enterprise specializing in the R&D and manufacturing of slewing bearings and slewing drives, Jingwei operates nearly 1,000 high-precision CNC machines and automated inspection equipment, establishing a comprehensive precision manufacturing and quality assurance system. Its mainstream products include single-row ball, double-row ball, and triple-row roller slewing bearings, as well as high-precision JP series, dual-worm drive, and open/closed horizontal slewing drives. These products are widely used in construction machinery, port equipment, new energy installations, and aerial work platforms. Currently, Jingwei's products are sold across multiple Chinese provinces and exported to Europe and America, forming long-term strategic partnerships with renowned OEMs. Moving forward, Jingwei will adhere to its development philosophy of "Continuous Improvement, Quality as the Foundation, Safety as the Priority, Customer First," increasing R&D investment to enhance product competitiveness and contribute more "Jingwei Power" to the high-quality development of the construction machinery industry!

In the accelerating wave of global energy transition, photovoltaic power generation, as a mainstay of green energy, has always focused on efficiency improvement and cost control. Recently, Jingwei New Energy officially launched its photovoltaic smart tracking system integrating "multi-point mechanical linkage + electrical coordination" technology, which not only precisely addresses industry pain points but also becomes a market favorite with significant "cost reduction and efficiency improvement" performance. Authoritative Validation: Tracking System Advantages Certified by National Data The National Photovoltaic and Energy Storage Demonstration Experimental Platform (Daqing Base) released its 2024 annual data results, providing authoritative endorsement for the superiority of tracking systems. The report shows: · Dual-axis tracking systems achieve the highest three-year power generation, averaging 24.58% higher than fixed-tilt systems (45° inclination). · Single-axis (10° inclination) systems outperform fixed-tilt systems by 64.44% during peak electricity pricing periods. · Tracking systems effectively compensate for the output limitations of fixed-tilt systems during grid peak hours, responding to grid load demands. Addressing Industry Pain Points: Traditional Tracking Systems Are Falling Behind! Are you also facing these challenges? · Insufficient Driving Force: Single-point drive in long-span, multi-component scenarios easily leads to angle desynchronization, significantly reducing power generation efficiency. · Poor Terrain Adaptability: Rigid structures struggle with complex terrains such as mountains and hills, resulting in large deviations in light-receiving angles. · High Extreme Weather Risks: Strong winds and heavy snows can cause concentrated structural stress, leading to system failure. · High Maintenance Costs: Complex installation and maintenance, coupled with difficult customization, limit the full lifecycle benefits. Solution: Dual-Linkage Synergy for 1+1>2 The next-generation smart tracking system, with "mechanical + electrical dual-linkage" as its core, breaks through technical bottlenecks: · Mechanical Innovation: Distributed multi-point drive + flexible linkage structures evenly distribute force, maintaining optimal light-receiving angles even on uneven terrain. · Electrical Upgrade: High-precision sensors + intelligent algorithms enable millisecond-level synchronization and north-south array coordination, significantly improving tracking accuracy. · Smart Extreme Weather Protection: Automatic wind-direction adjustment for resistance reduction and snow-shaking triggers enhance system reliability. Core Advantages: Increased Power Generation, Reduced Costs · Power generation efficiency surges by 15%-40% under complex lighting conditions compared to fixed systems. · Installation costs drop sharply by 0.6-1 cent/watt due to modular des...

Jingwei New Energy makes a heavyweight appearance at Intersolar Europe 2025, showcasing its technological innovation strength. Munich, May 7th, 8th, and 9th, 2025- Jingwei New Energy, a global leader in the photovoltaic and energy storage industry, showcased its latest technologies and products, as well as the latest breakthroughs in the field of smart energy solutions, at Intersolar Europe 2025 with multiple heavyweight products.

The highly anticipated international event for the solar energy industry, Intersolar EU 2025, will be held from May 7th to May 9th, 2025 in Munich, Germany. At that time, Ma'an Shan JingWei New Energy Drive Equipment Co.,LTD. will showcase various star products such as JL,JE,JV,JM etc. At the exhibition,showcasing JingWei New Energy’s innovative achievements and comprehensive strength to overseas customers. During the exhibition, we cordially invite colleagues and merchants from around the world to visit and exchange ideas at our booth, jointly painting a green landscape and creating a new chapter of sustainable development! Booth Number: A6 615 Exhibition Consultation:Manager Huang +0555-6615135

Bauma 2025 in Munich, Germany is the world's largest and most influential professional exhibition for the construction machinery industry. The exhibition will open on April 7, 2025 at the Munich New International Expo Center in Germany. The Bauma 2025 exhibition in Germany is the top event in the global construction machinery industry, attracting exhibitors and visitors from all over the world. The exhibition not only showcases the latest technologies and products, but also promotes communication and cooperation within the industry. Jingwei's product debut at the exhibition showcases innovative technologies and solutions, which can showcase its technology and products to the global market and further promote the development and progress of the industry. The purpose of Jingwei Company's exhibition is to grasp the international platform and deeply showcase innovative technologies and their achievements. At this exhibition, Jingwei showcased horizontal slewing drive, three row column type slewing bearing, and single row four point contact ball type slewing bearing for construction machinery. Its product features are higher accuracy , smoother transmission, and more reliable operation with a small body and large load capacity; Provide excellent stability and high load-bearing capacity, support customized design, and meet the special needs of the industry; Compact structure, light weight, suitable for various mechanical equipment, easy installation, low maintenance cost, multi-directional load-bearing capacity, stable operation in complex working environments. Jingwei has a complete range of products and advanced technology, and can provide professional customized services to customers, which has become one of the focuses of attention at the exhibition site. The exhibition in Munich, Germany (Bauma 2025) has successfully concluded. Bauma 2025 is not only an industry event, but also a window for Jingwei Company to showcase its innovation strength and strategic ambition to the world. Through technological breakthroughs, Jingwei is carving new coordinates on the global engineering machinery map under the name of "Made in China". With the advancement of green and intelligent trends, the globalization story of this Chinese enterprise may open a new chapter in the field of high-end equipment.

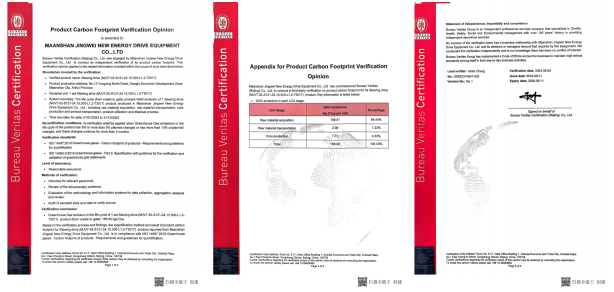

Recently, with its outstanding performance in the field of environmental protection, Jingwei Company has successfully obtained the certificate of product carbon footprint verification issued by an international authoritative organization. This milestone achievement not only highly recognizes the long-term commitment of Jingwei Company to sustainable development, but also sets a new benchmark for green development for global enterprises. This carbon footprint verification covers the relevant processes of Jingwei Company throughout the product lifecycle (from cradle to gate), including upstream raw material acquisition, raw material transportation, and product production. Throughout the entire process, Jingwei Company strictly followed international standards and effectively reduced the carbon emissions of its products through a series of measures such as optimizing production processes, adopting clean energy, and strengthening supply chain management. After verification, the carbon footprint of Jingwei Company's products is significantly lower than the industry average, demonstrating its strong strength in energy conservation and emission reduction. Obtaining a carbon footprint verification certificate is of great significance to Jingwei Company. This not only helps to enhance the company's brand image and market competitiveness, but also lays a solid foundation for the company to further expand into international markets. In today's world where environmental awareness is increasing, more and more consumers and customers prefer products with low-carbon environmental labels. The achievement of Jingwei Company will make it more attractive in the international market and win the trust and support of more partners. In the future, Jingwei Company will continue to adhere to the concept of green development and continuously increase investment and innovation in the field of environmental protection. We believe that under the leadership of Jingwei Company, more and more enterprises will join the ranks of green development, jointly contributing to the protection of our planet and promoting global sustainable development.

© Copyright: 2026 MA ANSHAN JING WEI SLEWING RING CO.,LTD. All Rights Reserved.

IPv6 network supported