6551 sets! New record ofjingwei!

6551 sets! New record of JINGWEI SLEWING RING CO.,LTD!

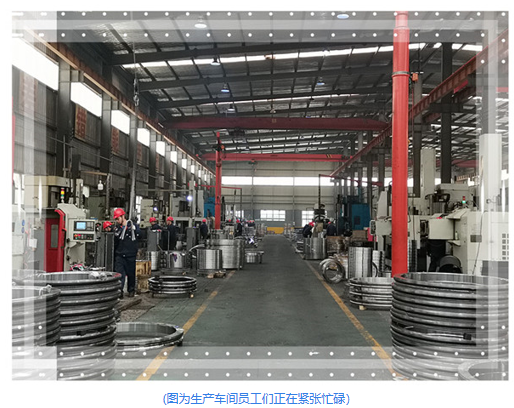

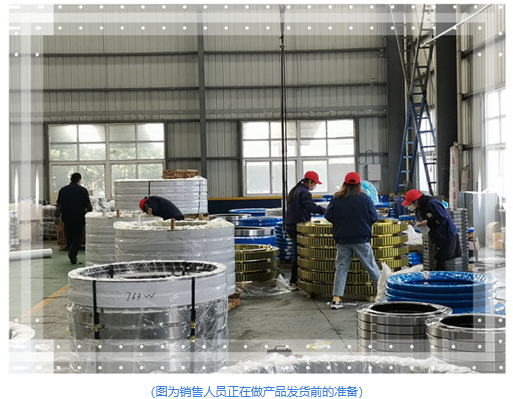

In March, when some production enterprises returned to work gradually after the epidemic eased, a record monthly output of slewing ring was born in JINGWEI NEW ENERGY DRIVE EQUIPMENT CO.,LTD. 6551 sets, the second month after the resumption of production, Jingwei Company broke through the obstacles of the epidemic and handed in a beautiful answer sheet to the society and customers with its best performance in history.

That product is the double row ball slewing bearing.The double row ball slewing bearing has three seat rings. The steel balls and isolation blocks can be directly discharged into the upper and lower raceways. According to the stress conditions, two rows of steel balls with different diameters are arranged. This kind of open assembly is very convenient. The bearing angles of the upper and lower arc raceways are all 90 °, which can bear large axial force and overturning moment. When the radial force is greater than 0.1 times of the axial force, the raceway must be specially designed. The axial and radial dimensions of the double volleyball slewing bearing are relatively large, and the structure is tight. It is especially suitable for tower crane, truck crane and other loading and unloading machinery requiring medium or above diameter.There are three types of products:No teeth(020),Outer teeth(021.002) and Inner teeth(023.024). This product is a tight structure,large axial radial dimensions slewing bearing, it is also a loading unloading machinery slewing bearing.What is more ,it is a No teeth,Inner teeth and Outer teeth slewing ring.

As one of the less than 10 enterprises in the county economic development zone that have been approved to return to work, Jingwei Company started to intervene in the return to work application procedure as early as the end of January. After returning to work on February 10, the company strictly controlled the epidemic prevention and control to ensure that there was no risk; while comparing the backlog and new orders, the company made every effort to press the fast forward button of returning to work. Under the organization and coordination of the company, the return rate of employees quickly recovered from 83% on the first day of return to work and remained stable at over 97.8% in March, higher than the benchmark level of peers in the whole month, and the equipment opening rate reached 100% every day. In addition, in order to make up for the delayed delivery time affected by the epidemic as soon as possible, and to meet the urgent needs of domestic host manufacturers and foreign customers in Europe and the United States, from March 1, the production line of the company started the emergency adjustment mechanism of operation time on the whole line, and implemented the "210" working system within 24 hours, that is, two shifts per day, 10 hours per shift, and even longer individual node processes. Under the guidance of the enterprise concept of "customer-oriented", all employees strive to carry forward the "Jingwei spirit" of daring to fight, overcome many difficulties, and release the work passion suppressed by the epidemic for several days. On the basis of 10 hours, some employees come early and leave late, and actively increase the working time, so that the output in March leaps to the highest point in history, meeting the needs of customers to the greatest extent , and there was no customer order cancellation event during this period.

In addition, it is understood that after April, the order quantity of Jingwei Company is still in the state of full load production, and the resumption of production will continue to maintain high-level operation.

Blog Categories

Application

© Copyright: 2026 MA ANSHAN JING WEI SLEWING RING CO.,LTD. All Rights Reserved.

IPv6 network supported