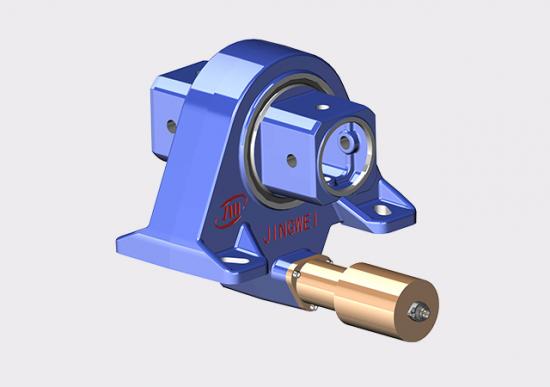

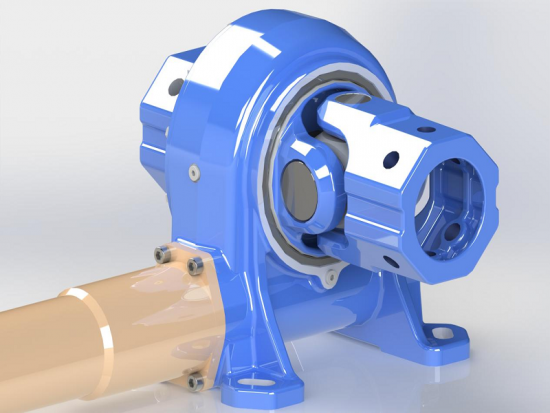

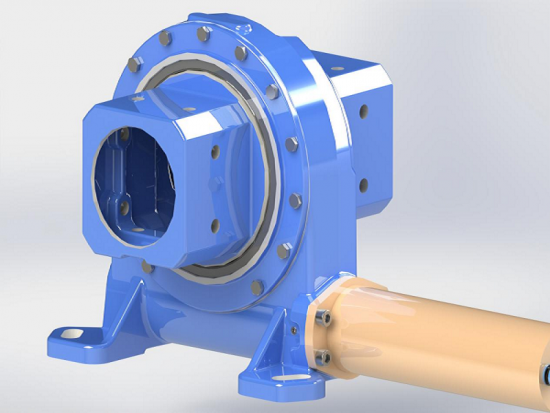

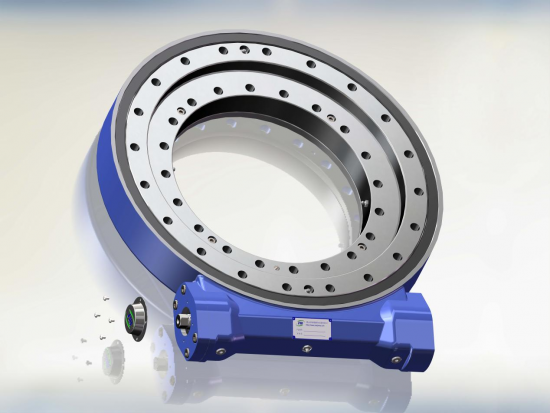

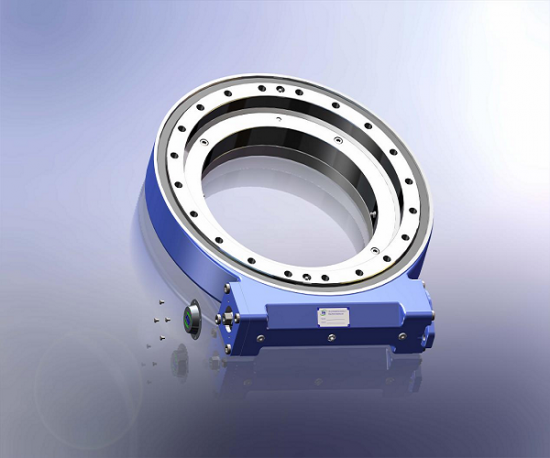

JS17 slewing reducer series

Product features:

1. The horizontal structure allows the product to be installed horizontally, vertically, and obliquely, with the characteristics of flexible and diverse installation. Compared with other types of reducers, it has the characteristics of small volume, easy installation and maintenance.

2. The product adopts a blind hole design and a skeleton oil seal structure, with reliable sealing performance. The sealing area can avoid direct sunlight, effectively dust-proof and waterproof, and the protection level can reach IP65, suitable for outdoor use.

3. Use specialized machine tools and equipment to produce toroidal worm gears with multiple teeth in contact, transmitting greater torque and being able to withstand greater axial, radial, and overturning forces.

4. The product design adopts universal dimensions both domestically and internationally, making it convenient for later replacement.

Application scope:

1. Used for the horizontal rotation of solar tracking systems, and can also be applied to the rotation of certain special engineering machinery and industrial equipment.

Various types of construction machinery chassis rotation or boom rotation

Rotation of the chassis of high-altitude work vehicles

2. Applied to photovoltaic single and dual axis tracking systems, concentrated photovoltaic tracking systems, tower style heliostats, dish style Stirling power generation, trough style concentrated heat generation heating systems, etc.

Application advantages:

1. The surface of the product is subject to secondary electrostatic powder spraying in multiple processes, and the use of epoxy zinc rich primer and epoxy resin flour greatly improves the corrosion resistance and aging resistance of the product. Neutral salt spray test for more than 1000 hours.

2. The raceway and gear tooth surface of the slewing support have undergone quenching treatment, resulting in high hardness and strong rigidity.

3. It has a self-locking function, which improves the safety of use.

4. The transmission accuracy can reach 1 milliradian (1mard).

5. The product is developed based on the principle of maintenance free, with minimal maintenance.

6. The load and overturning torque borne by the product are greater than those of similar products in the market.

7. The product has undergone high and low temperature tests and has strong temperature resistance.

8. Adopting national high-tech graphene synthetic lubricating grease, its lifespan and heat dissipation efficiency far exceed ordinary lubricating grease.

9. Adopting a toroidal worm design, with multiple teeth in contact and carrying a large output torque.